MSL93

Structural

- Aug 10, 2017

- 5

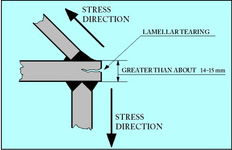

I have seen an uptick in customer specifications that state the need to do ultrasonic testing to check for lamellar defects in steel plates. The specifications will generally be vague on the details for what constitutes what needs to be tested. For example, they will say things like "Plates subject to high, localized through-thickness strain" but not list any criteria for what constitutes what is considered "high" or "thick plates subjected to bending stresses" but not list any criteria of what a thick vs. non-thick plate is (greater than 1" thick, greater than 2" thick, etc.).

My question is does anyone know of any good references that I can look into to fill in the knowledge gap here to better understand how to apply these customer specifications?

My question is does anyone know of any good references that I can look into to fill in the knowledge gap here to better understand how to apply these customer specifications?