Does anyone know of any technical data for "re-heeling an existing truss"?

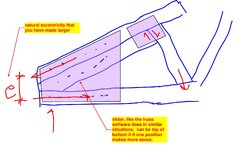

More specifically, the analysis process for removing the existing bearing of an existing truss and providing a new hanger support. The procedure would be as follows:

1. Shore truss,

2. Cut back overhang and bearing so the new end of truss is flush with interior wall (at concrete/masonry) or ledger etc.

3. Provide plywood sheathing each side to reinforce end of new truss heel.

4. Rehang the truss with new hanger.

I'm already familiar with the theoretical approach to reinforcing the web members with plywood sheathing.

My real concern here is how this modification can inadvertently change the stiffness of the truss or create propensity for additional deflection.

More specifically, the analysis process for removing the existing bearing of an existing truss and providing a new hanger support. The procedure would be as follows:

1. Shore truss,

2. Cut back overhang and bearing so the new end of truss is flush with interior wall (at concrete/masonry) or ledger etc.

3. Provide plywood sheathing each side to reinforce end of new truss heel.

4. Rehang the truss with new hanger.

I'm already familiar with the theoretical approach to reinforcing the web members with plywood sheathing.

My real concern here is how this modification can inadvertently change the stiffness of the truss or create propensity for additional deflection.